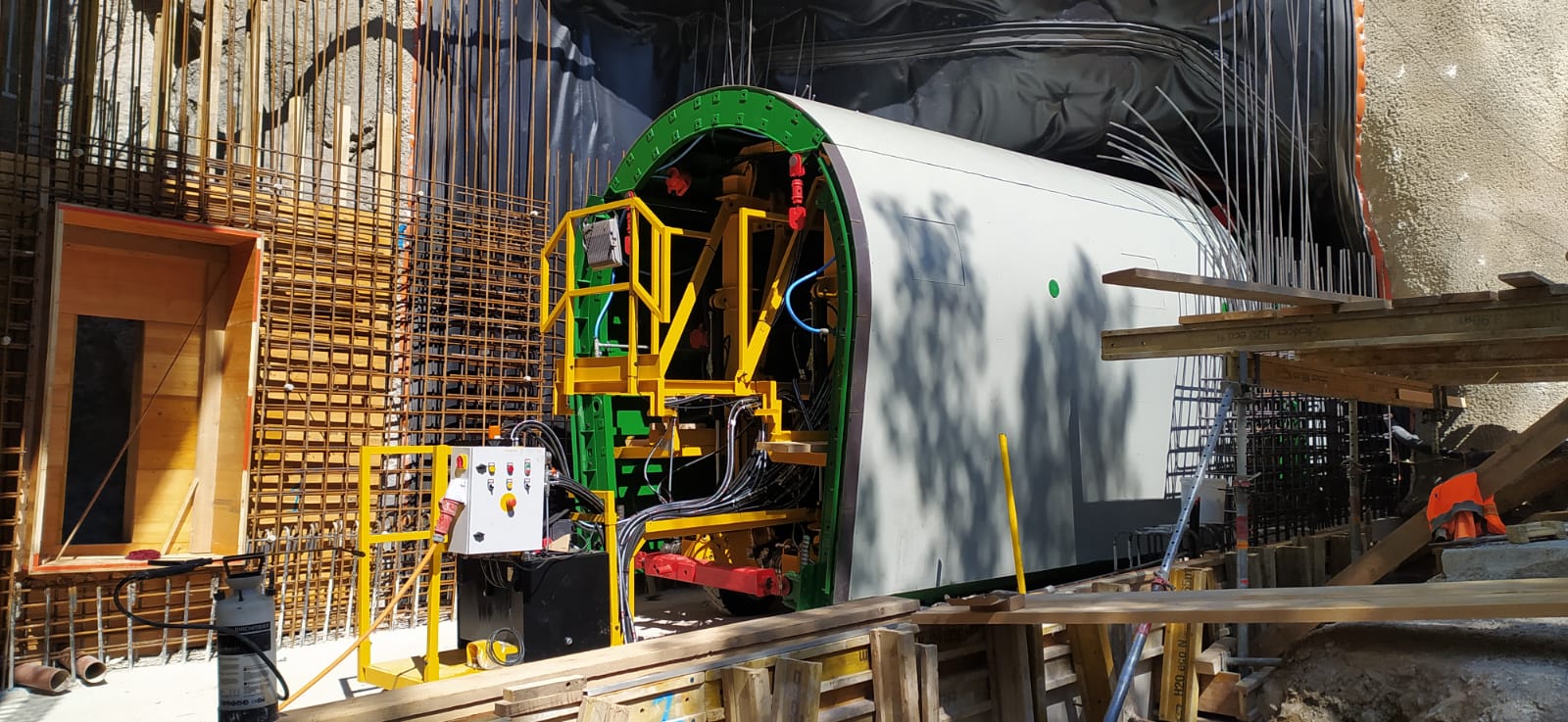

Security Cavern Formwork in La Clusette, Switzerland.

Customer: Infra Tunnel, S.A.

Country: Switzerland

Location: La Clusette

Year: 2023-ongoing

Description:

This is a safety cavern formwork with a solid rubber motorized wheel designed for movement on uneven and multi-surface terrains. This device is specifically engineered to ascend slopes with a longitudinal incline of over 12%, and it features a hydraulic braking system for safety assurance.

A standout feature of this equipment is the solid plastic coating ALKUS®. This coating not only reduces maintenance and lubrication requirements but also enables the creation of excellent concrete surfaces.

Furthermore, this equipment includes a concrete piping system that comes pre-installed, even in very compact dimensions, streamlining project execution.

The equipment has a total length of 10 meters and features a quick system for splitting it into two sections of 5 meters each, particularly beneficial for tasks involving curved sections. Each of these 5-meter sections can be operated independently, enhancing versatility and efficiency at the work site.

Security Cavern Formwork in La Clusette, Switzerland.

Customer: Infra Tunnel, S.A.

Country: Switzerland

Location: La Clusette

Year: 2023-ongoing

Description:

This is a safety cavern formwork with a solid rubber motorized wheel designed for movement on uneven and multi-surface terrains. This device is specifically engineered to ascend slopes with a longitudinal incline of over 12%, and it features a hydraulic braking system for safety assurance.

A standout feature of this equipment is the solid plastic coating ALKUS®. This coating not only reduces maintenance and lubrication requirements but also enables the creation of excellent concrete surfaces.

Furthermore, this equipment includes a concrete piping system that comes pre-installed, even in very compact dimensions, streamlining project execution.

The equipment has a total length of 10 meters and features a quick system for splitting it into two sections of 5 meters each, particularly beneficial for tasks involving curved sections. Each of these 5-meter sections can be operated independently, enhancing versatility and efficiency at the work site.